- Manufacturing

- Total Solutions

- Services

- Recurring Income Business

- Our Products and Services

- Our Valued Clients

|

||

|

|

| . | . | . | |

| Our Products and Services |

|||

| Quench Coolers | |||

| Process Gas Waste Heat Recovery Systems |

1. "Tunnelflow" - Gasinlet Tubesheet Design | ||

| Membrane Technology Systems |

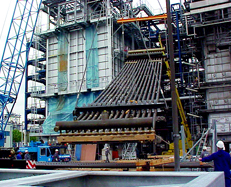

2. Borsig Linear Quencher | ||

| Sour Gas & Sulfur Technology |

The KNM' Borsig BLQ is a modulized design which permits a very narrow spacing of the double pipes and allows tube configurations which perfectly meet the individual coil and furnace layout requirements. The pipes can be arranged linearly or with offset arrangement if required. The very narrow inline pipe spacing is possible due to individual manufacture of the double pipe elements. Performing the weld of the outer pipe to the water chamber is not impaired by a close location of the neighbouring pipe.

After the pipes are individually manufactured and non-destructively tested, they are assembled to a register of double pipes with all necessary headers, nozzles, brackets and supports. The pipe spacing can be as close as the O.D. of the outer pipe, if required. The “Turboflow” chamber design allows the number of coils in a single radiant coil module with the same narrow spacing to be practically unlimited. It is conceivable that future furnace designs could have radiant coil modules consisting of 48 narrow spaced radiant coils. In this case the 48 tube BLQ module would be shipped in two parts for site assembling. The BLQ can be designed and manufactured according to all international recognized codes and standards such as German AD-Merkblatter, ASME etc. |

||

| Compression Systems |

|||

| Fired & Heat Recovery Boilers |

|||

| Quench Coolers |

|||

| Scraped Surface Exchangers |

|||

| Process & Pressure Vessels |

|||

| Heat Transfer Equipment |

|||

| Storage Facilities & Terminals |

|||

| Process Skid Packages & Modules |

|||

| Industrial & Power Plant Services |

|||

|

|||

Quench Coolers Borsig Linear Quencher |

|

|

|||