- Manufacturing

- Total Solutions

- Services

- Recurring Income Business

- Our Products and Services

- Our Valued Clients

|

||

|

|

| . | . | . | |

| Our Products and Services |

|||

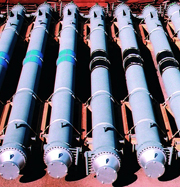

| Quench Coolers | |||

| Process Gas Waste Heat Recovery Systems |

1. "Tunnelflow" - Gasinlet Tubesheet Design | ||

| Membrane Technology Systems |

2. Borsig Linear Quencher | ||

| Sour Gas & Sulfur Technology |

The gas produced by cracking, which leaves the furnace at a temperature of around 850°C (1500°F), must be cooled down rapidly (quenching) after leaving the reaction zone of the furnace in order to prevent secondary reactions and to stabilize the gas composition in order to obtain the optimum product yield. In all modern ethylene processes this rapid cooling of the cracked gas is done with quench coolers (also known as transfer line exchangers or TLEs) thereby producing high pressure steam.

|

||

| Compression Systems |

|||

| Fired & Heat Recovery Boilers |

|||

| Quench Coolers |

|||

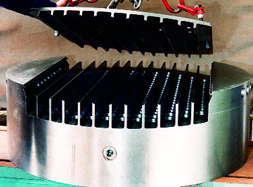

| Scraped Surface Exchangers |

|||

| Process & Pressure Vessels |

|||

| Heat Transfer Equipment |

|||

| Storage Facilities & Terminals |

|||

| Process Skid Packages & Modules |

|||

| Industrial & Power Plant Services |

|||

Quench Coolers |

|

|

|||