- Manufacturing

- Total Solutions

- Services

- Recurring Income Business

- Our Products and Services

- Our Valued Clients

|

||

|

|

| . | . | . | |

| Our Products and Services |

|||

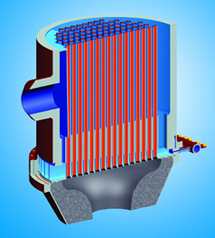

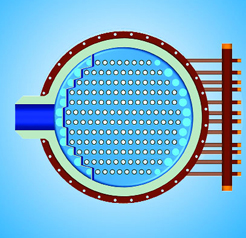

| Quench Coolers | |||

| Process Gas Waste Heat Recovery Systems |

1. "Tunnelflow" - Gasinlet Tubesheet Design | ||

| Membrane Technology Systems |

2. Borsig Linear Quencher | ||

| Sour Gas & Sulfur Technology |

A thick tubesheet is impracticable because metal temperature of the tubesheet would be too high due to heat transport from the gas into the tubesheet.

The patented BORSIG linear quencher (BLQ) consists of a number of linearly arranged double pipe elements of which each is directly coupled to one of the furnace radiant coil outlets. The process effluent from each single radiant coil is quenched individually in its own double pipe element. A common downcomer header distributes uniformly the circulating boiler water coming from the steam drum to each of the “Turboflow” inlet chambers. A riser header is collecting the steam/water mixture from the upper outlet chambers. |

||

| Compression Systems |

|||

| Fired & Heat Recovery Boilers |

|||

| Quench Coolers |

|||

| Scraped Surface Exchangers |

|||

| Process & Pressure Vessels |

|||

| Heat Transfer Equipment |

|||

| Storage Facilities & Terminals |

|||

| Process Skid Packages & Modules |

|||

| Industrial & Power Plant Services |

|||

|

|||

Quench Coolers "Tunnelflow" - Gasinlet Tubesheet Design |

|

|

|||